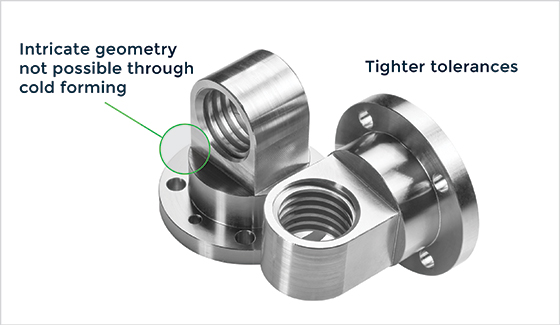

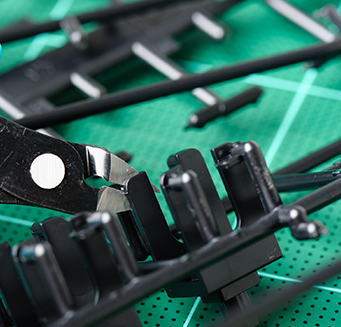

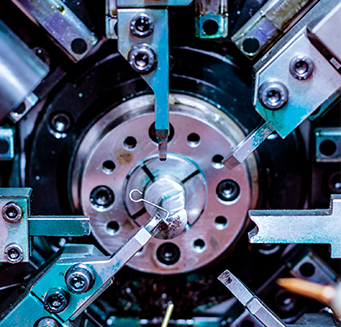

Expertise is Key...

That's why we have engineers on staff dedicated to your next project. It's why we are experienced in more than 25 manufacturing technologies. And it's why the "international" in our name means more than location. The expertise of our team spans the globe.